Silicone solid state compression molding process:

Silicone calenders generally use vertical three- and five-roll calenders and drum calenders. When producing silicone sheets, the calendering speed should not be too fast. First adjust the roll distance (middle and bottom rolls) at a low speed to ensure a certain The thickness is rolled and then increased to normal speed for continuous operation. The rubber material used for calendering must be properly controlled for its degree of re-refining. It is best to not fully re-refining on the rubber mixing machine in order to obtain sufficient re-refining during the calendering process, so as to avoid excessive re-refining of the rubber during the calendering process. And sticky roller. Mainly used for larger products, such as silica gel sheets and silica gel plates.

Product specifications:

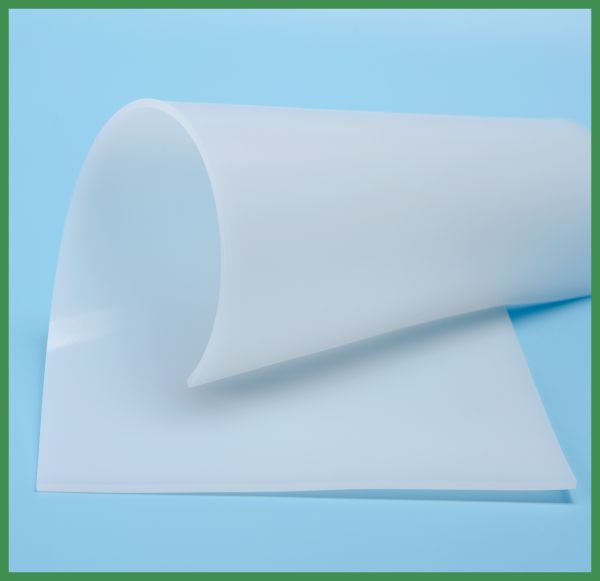

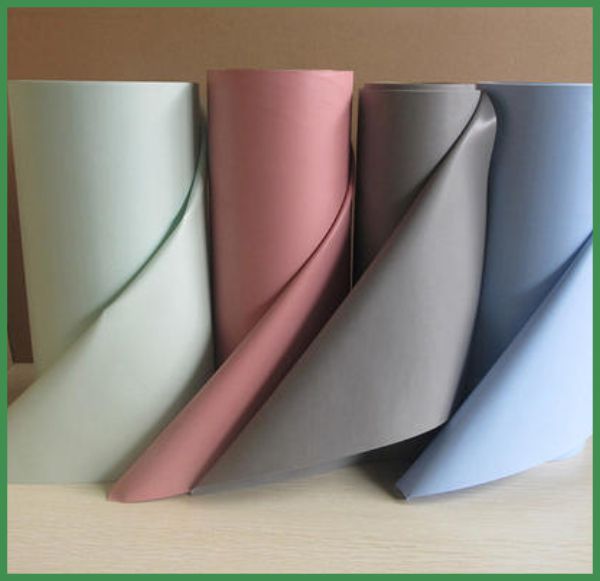

The width of the silicone plate is 300mm/500mm/1000mm, and the thickness is 0.1-2mm

Product Features:

▪Silica gel plate is a sheet-like product with a certain thickness and a large area made by vulcanizing silica gel as the main material.

▪ It is made by calendering the rubber compound or extrusion molding, and vulcanizing with a flat vulcanizing machine or continuously vulcanizing with a drum vulcanizing machine.

▪ High adsorption performance, good thermal stability, stable chemical properties, high mechanical strength, etc.

Main product categories, names, characteristics and MSK raw materials

Silicone semi-finished materials SiParts

Able to meet future needs

Suitable for various industrial fields and multiple purposes.

By combining organic and inorganic materials, Improve the chemical and physical properties of materials.

Has a stable structure