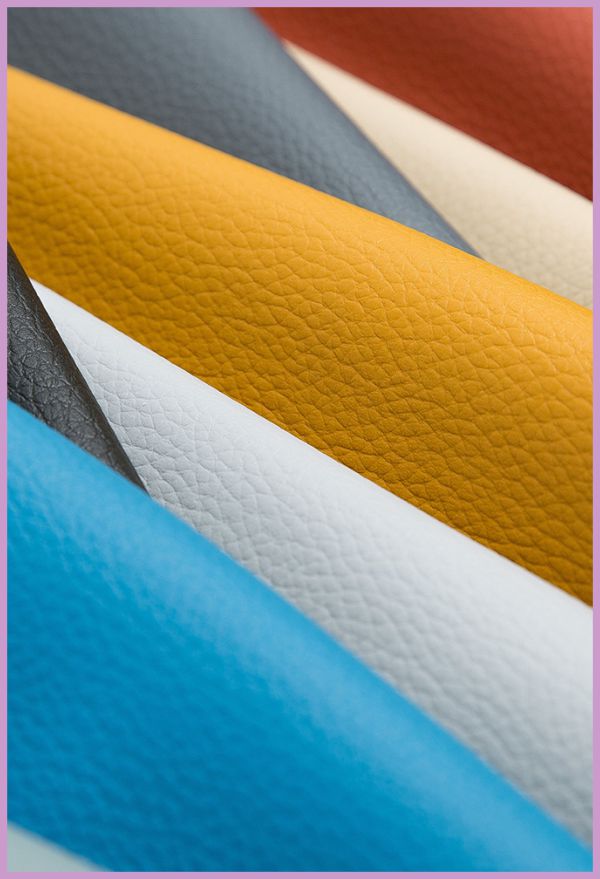

Liquid coated silicone leather, glass fiber cloth

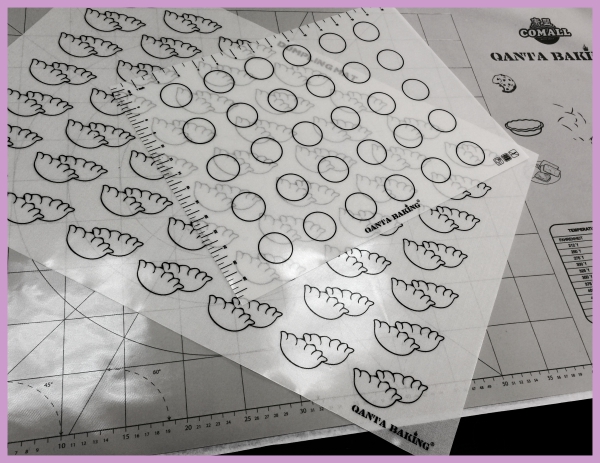

Equipment capacity: 1 double-sided liquid coating line for silicone cloth, 1270mm wide 10m tunnel oven; 1 single-sided liquid coating line for silicone leather, 1400mm wide 50m tunnel oven. 1 set of silicone coating machine, 1 set of release paper inspection machine, 1 set of elastic fabric inspection machine, 1 set of finished product sub-roll inspection machine, 2 sets of fabric heat splicing machine.