Multi-layer composite processing materials

KIREI REZA ® silicone leather composite TPU double-sided hot-melt adhesive film can be hot-pressed and laminated on ABS, PC, TPE, metal, etc. It can be applied to high-end flat keyboards and shells to show the effect of silicone skin texture!

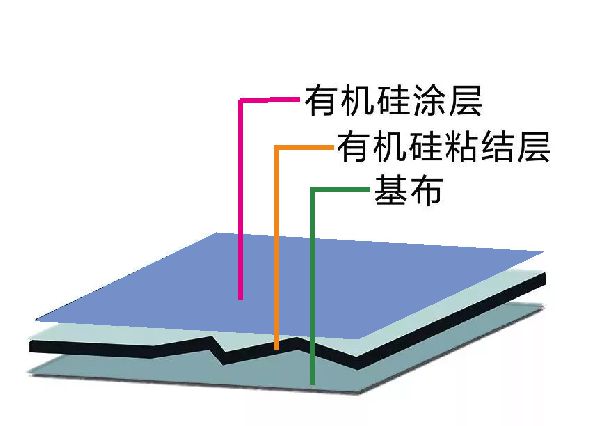

KIREI REZA ® silicone leather composite processing, the coated substrate is not only the cloth surface, but also TPU/PET/silicone film/glass fiber cloth can be processed through composite technology, which expands the ability of hot pressing and composite adhesion in the subsequent process. The technology comes from Kangda Technology Group!

The combination of KIREI REZA ® silicone leather 3M300SLE double-sided tape and die-cut patch of 3C products. The silicone leather can be perfectly attached to the outer surface of metal, PC, ABS, etc., which greatly enhances product value and protection, which is very revolutionary. Sexual breakthrough!