Silicone solid state compression molding process:

Extruded silica gel products are usually formed by extruding silica gel through an extrusion machine. It is a continuous molding process and can be suitable for the production and processing of double ditetrasulfide solid silica gel or platinum vulcanizing agent catalyzed solid silica gel. It is a process in which silicone rubber is continuously made into semi-finished products of various shapes under the interaction of the barrel of the silicone extruder and the rotating screw. It can be used to process silicone products such as silicone tubes and silicone strips.

Product specifications:

Can be customized according to customer requirements

Product Features:

▪Using high-grade silicone material, non-toxic, odorless and harmless, it is a real green environmental protection product

▪Abrasion resistance, high temperature resistance, non-deformation and other characteristics, long service life

▪Soft texture, high bionicity, suitable for babies

▪ The product complies with the EU LFGB standard

Main product categories, names, characteristics and MSK raw materials

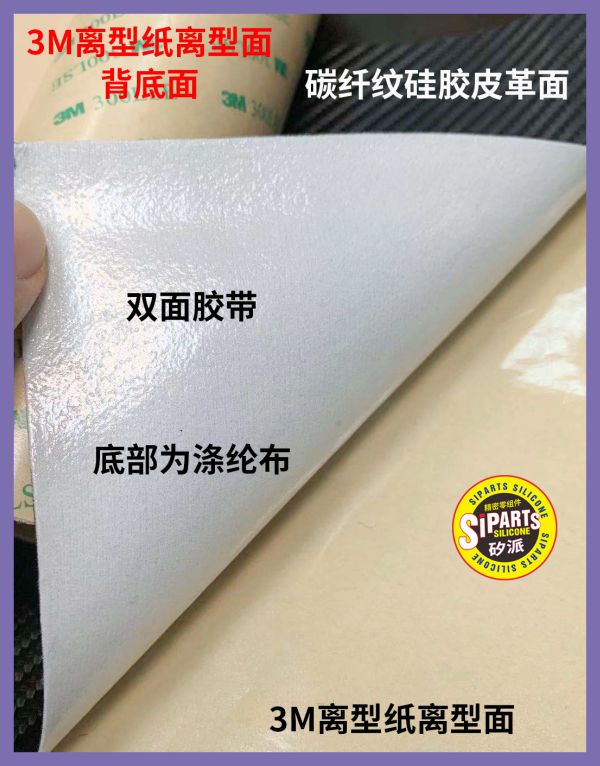

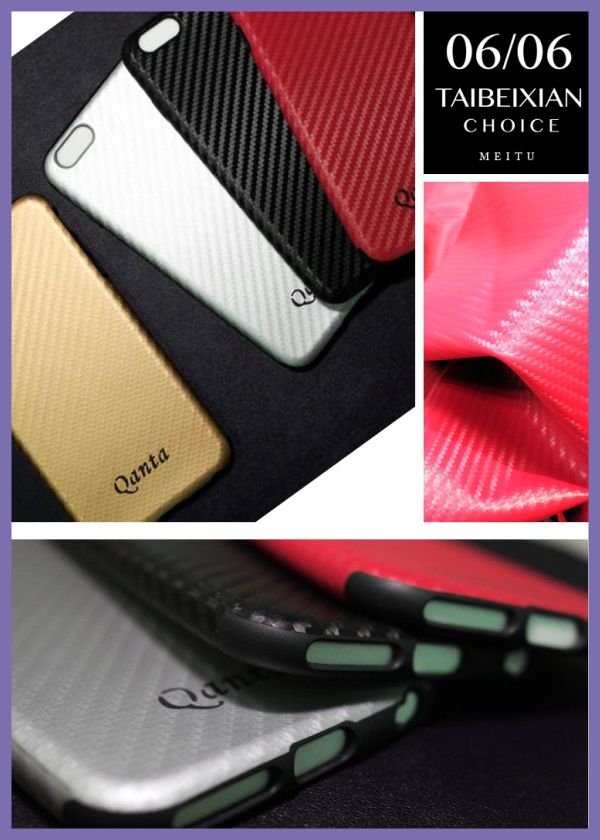

Silicone semi-finished materials SiParts

Able to meet future needs

Suitable for various industrial fields and multiple purposes.

By combining organic and inorganic materials, Improve the chemical and physical properties of materials.

Has a stable structure